Posters

The size matters!

The poster is an exceptionally effective and a mighty powerful way to make you campaign, event or goods distinguished.

In Classic Desigh we can print not only using the standard A2, A3 but also up to 50x70cm. The weight of the paper can vary from 90 tu 200gr/m2. We can offer you to protect your posters with attitional and elegant UV warnish or laminate.

To ensure high quality, we would need you to supply:

Suitable for printing, composite PDF in CMYK, or CMYK + Spot colors, without ICC profiles, passers, scales or any other signs. The resolution of the images must be 300dpi or higher. Layout must have an extention on all sides.

For more information contact Classic Design team.

Finishing Works

- UV WARNISHING : MATT OR GLOSS OR SPOT

- OVERCOATING MATT, OVERCOATING GLOSS

- LAMINATING GLOSS OR LAMINATING -MATT

- CREASING

- EMBOSSING

- FOIL BLOCKING

- DIE - CUTTING

UV WARNISHING MATT/GLOSS/SPOT In this process printed area is covered with the special coating and is then exposed to the UV light. Photo-initiators within the coating react, creating a hard protective finish. Ingredients provide gloss or matt characteristics. It can be applied as an all-over coat or in spots to highlight a specific area. The varieties of effects that can be achieved are endless, when using different combinations of laminate, varnish and ink.

UV WARNISHING MATT/GLOSS/SPOT In this process printed area is covered with the special coating and is then exposed to the UV light. Photo-initiators within the coating react, creating a hard protective finish. Ingredients provide gloss or matt characteristics. It can be applied as an all-over coat or in spots to highlight a specific area. The varieties of effects that can be achieved are endless, when using different combinations of laminate, varnish and ink.This is applied during the printing process varnish, like any other ordinary solvent-based ink. The varieties of over-coating varnish are usually colourless, but sometimes they are tinted to achieve a desired effect. Varnish can be applied as an all-over coat or in spots to highlight a specific area. It is available in glossy or satin finishes. The varieties of effects that can be achieved are endless, when using different combinations of varnish, paper, and ink.

LAMINATING GLOSS OR LAMINATING – MATT

LAMINATING GLOSS OR LAMINATING – MATTLaminating is the process of applying a clear film to either one side or both sides of a printed document. Applying laminate provides protection to printed products that are handled frequently or may encounter moisture.

FOIL BLOCKING When a specific print area requires an elegant finish, it is easily accomplished using foil blocking (also named hot stamping when heat is applied). The process adhere the foil onto the area requiring the metallic effect. The result is a highly reflective image with a bright and dense metallic appearance. Foils can be used for logos, borders, titles or elegant accents for distinctive symbols, graphics, or lines.

FOIL BLOCKING When a specific print area requires an elegant finish, it is easily accomplished using foil blocking (also named hot stamping when heat is applied). The process adhere the foil onto the area requiring the metallic effect. The result is a highly reflective image with a bright and dense metallic appearance. Foils can be used for logos, borders, titles or elegant accents for distinctive symbols, graphics, or lines.

DIE-CUTTING Die-cutting involves the use of metal dies constructed of knife-edge cutting blades formed into a pattern or die. The die is pressed into the substrate to produce the desired shape. Almost any shape can be created and applied to a diverse array of raw materials. Labels, envelopes, folders, cartons, and documents are only a few of the many products that can be die cut for added functionality.

DIE-CUTTING Die-cutting involves the use of metal dies constructed of knife-edge cutting blades formed into a pattern or die. The die is pressed into the substrate to produce the desired shape. Almost any shape can be created and applied to a diverse array of raw materials. Labels, envelopes, folders, cartons, and documents are only a few of the many products that can be die cut for added functionality.Glossary

- WIRE STITCHING (SADDLE STITCHING)

- WIRE STITCHING (SIDE STITCHING)

- PERFECT BINDING (SOFT COVERING)

- THREAD SEWING + PERFECT BINDING (SOFT COVERING)

- HARD COVERING

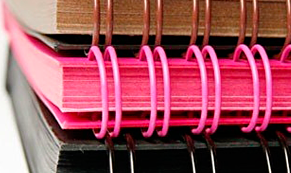

- SPIRAL WIROBINDING

- COVER WITH FLAPS

- COVER WITH DUST JACKET

- ORIENTATION PORTRAIT/ALBUM

WIRE STITCHING (SIDE STITCHING) Side wire stitching is generally for booklets or books that contain too many pages to be effectively saddle stitched. The sheets are bound on the side of the book. The staples are inserted from the front side of the book, through the pages, and are pinched closed on the back side of the book. Side wire binding does not allow the book to be opened as flat as a saddle stitched book and an extra allowance for the inner margin must be made for the stapled stub.

WIRE STITCHING (SIDE STITCHING) Side wire stitching is generally for booklets or books that contain too many pages to be effectively saddle stitched. The sheets are bound on the side of the book. The staples are inserted from the front side of the book, through the pages, and are pinched closed on the back side of the book. Side wire binding does not allow the book to be opened as flat as a saddle stitched book and an extra allowance for the inner margin must be made for the stapled stub.

THREAD SEWING + PERFECT BINDING (SOFT COVERING) This method is most durable. The printed sheet containing individual book pages, called a signature, is folded, and assembled in the correct page order. After this, the signature is sewn together with other signatures. The sewn edge (spine) of the book is coated with glue. A cover is attached to the book and is held in place by the glued spine.

THREAD SEWING + PERFECT BINDING (SOFT COVERING) This method is most durable. The printed sheet containing individual book pages, called a signature, is folded, and assembled in the correct page order. After this, the signature is sewn together with other signatures. The sewn edge (spine) of the book is coated with glue. A cover is attached to the book and is held in place by the glued spine.

HARD COVERING A number of steps are required to complete a bound book. First, a large printed sheet containing individual book pages, called a signature, is folded and assembled in the correct page order. The signature is sewn together with other signatures. End-leaf papers are glued to the outside of the first and last signatures. The sewn edge (spine) of the book is coated with glue and a strip of gauze is wrapped around it. The heavy board covers are wrapped with paper, cloth, or other materials to form the final book covering. The book is attached to its hard cover by sticking end-leaf papers to the case. Final step is to insert the book into a hydraulic press to ensure that it dries properly and does not warp.

HARD COVERING A number of steps are required to complete a bound book. First, a large printed sheet containing individual book pages, called a signature, is folded and assembled in the correct page order. The signature is sewn together with other signatures. End-leaf papers are glued to the outside of the first and last signatures. The sewn edge (spine) of the book is coated with glue and a strip of gauze is wrapped around it. The heavy board covers are wrapped with paper, cloth, or other materials to form the final book covering. The book is attached to its hard cover by sticking end-leaf papers to the case. Final step is to insert the book into a hydraulic press to ensure that it dries properly and does not warp.

SPIRAL WIROBINDING A spiral binding consists of a continuous wire, which is coiled through evenly spaced holes that have been punched into the pages of a book. The spiral wire can be made of metal, plastic, or plastic coated metal. Plastic is available in a variety of colours, but the metal spiral has a limited colour selection. When the books are open, the pages lie flat, which makes spiral binding a good choice for training manuals, cookbooks, and calendars.

SPIRAL WIROBINDING A spiral binding consists of a continuous wire, which is coiled through evenly spaced holes that have been punched into the pages of a book. The spiral wire can be made of metal, plastic, or plastic coated metal. Plastic is available in a variety of colours, but the metal spiral has a limited colour selection. When the books are open, the pages lie flat, which makes spiral binding a good choice for training manuals, cookbooks, and calendars.

Full Canadian (Square Back) – The partially hidden wire-o is exposed on the front and back cover. Flat spine allows for easy identification.

Full Canadian (Square Back) – The partially hidden wire-o is exposed on the front and back cover. Flat spine allows for easy identification.

Catalogue/Publishers – An intriguing one-piece cover style that opens “in reverse”, creating a flat spine for identifi cation.

Cased In – Standard wire-o pasted into a hard case with all the advantages of opening.

Cased In – Standard wire-o pasted into a hard case with all the advantages of opening.

Reverse Binding – Allows for an expandable inside cover where a large spread image is important.

Reverse Binding – Allows for an expandable inside cover where a large spread image is important.

The binding is hidden and the spine is flat. Back flap can be pasted down or left free.

Standard Binding – Most common cover style. Separate front and back covers.

Standard Binding – Most common cover style. Separate front and back covers.

Opens easily back – to back.

COVER WITH DUST JACKET The dust jacket (sometimes book jacket, dust wrapper or dust cover), is the detachable outer cover, usually made of paper and printed with text and illustrations. This outer cover has folded flaps that hold it to the front and back book covers. In addition to its promotional role, the dust jacket protects the book covers from damage.

COVER WITH DUST JACKET The dust jacket (sometimes book jacket, dust wrapper or dust cover), is the detachable outer cover, usually made of paper and printed with text and illustrations. This outer cover has folded flaps that hold it to the front and back book covers. In addition to its promotional role, the dust jacket protects the book covers from damage.